Surface treatment for Environmental plants

Surface treatment for Environmental plants that applies hardfacing technology honed through manufacturing and flexible response from the customer's perspective

Waste incineration plants across the country are moving to harsher operating conditions to improve the efficiency of energy recovery and respond to dioxin pollution issues, and with the adoption of the public·private·operated (DBO :Design Build Operate) system, there is a growing need for longer life, and even higher corrosion resistance is required for wear-and·tear objects within the facility. FUJICO provides surface treatments (welding, thermal spraying, etc.) such as nickel alloy to the walls and wear-and·tear equipment of environmental plant facilities and incinerators, achieving oxidation resistance and corrosion resistance in high-temperature environments.

We are handling not only production in our factories but also on-site surface treatment of existing facilities.

Products

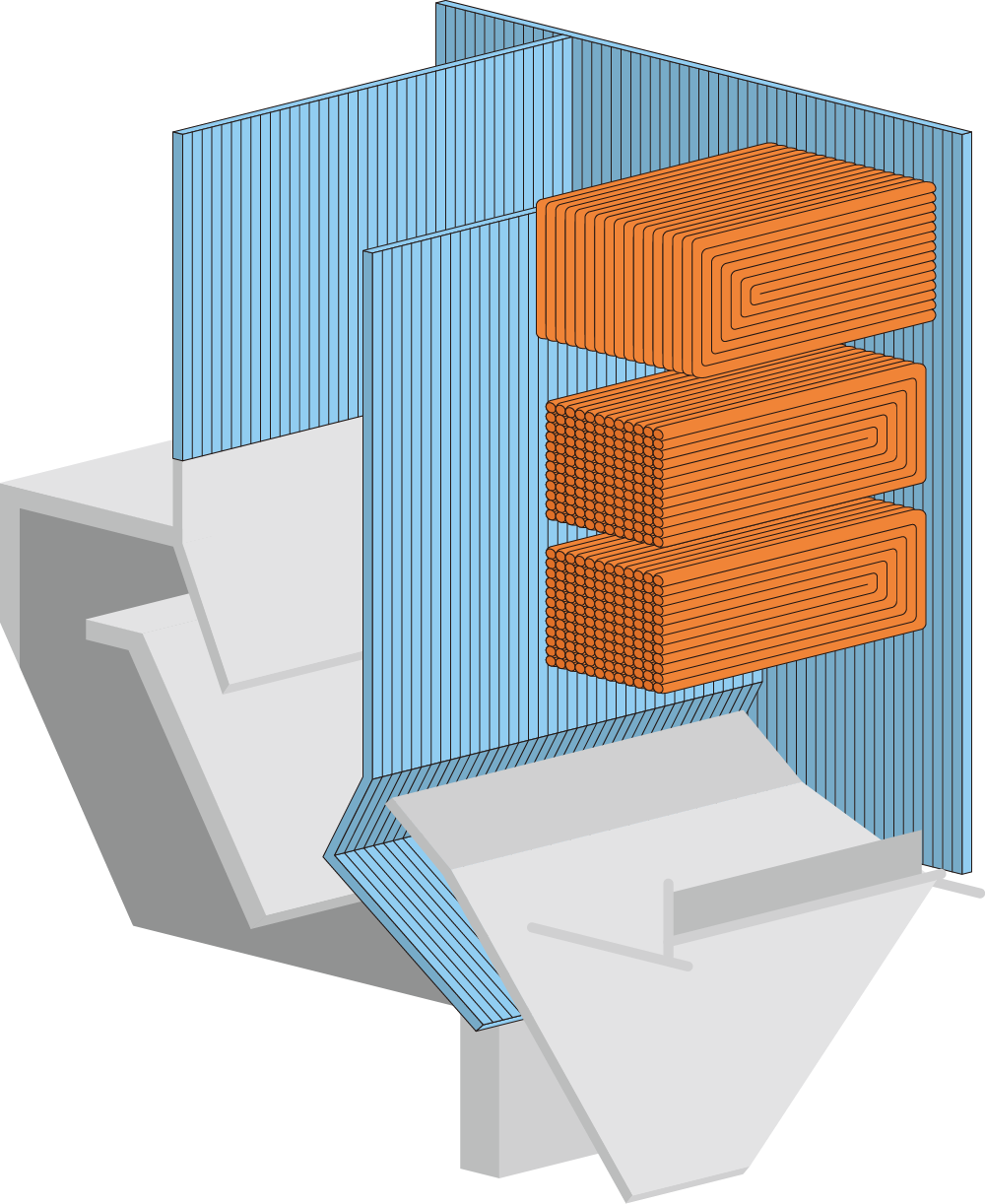

●Water Cooling Panel in combustion chamber

As combustion chambers are the most severely affected by heat and gas,

FUJICO has provided the surface treatment for the water cooling panel with either welding or thermal spraying process.

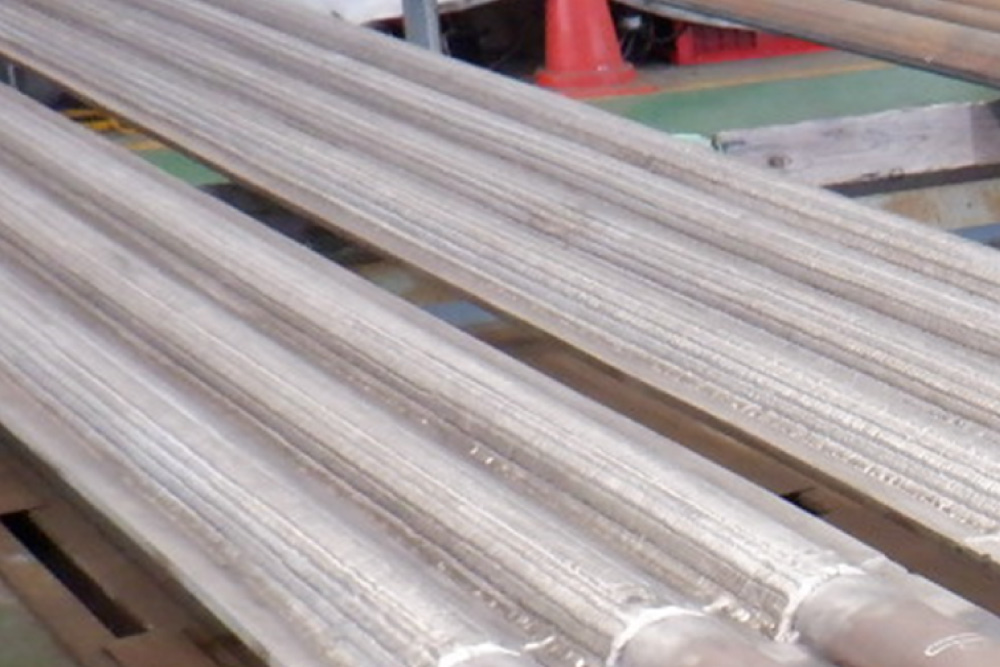

●Superheater's Pipes

Pipes of superheaters are essential for effective use of the thermal energy of combustion gases,

and their outer circumferences are treated with hard-facing process.