Cast Welding

The secret of power is original mass-volume cladding technology,

characterized by overwhelming durability.

Cast welding technology, forming a very thick clad layer, is FUJICO's original composite technology that has achieved high performance and low cost. With cladding materials using substantial carbon and chromium, FUJICO has made an exclusive achievement in sintered ore-crushing equipment for ironmaking plants in Japan and overseas.

FUJICO's Original Cast Welding

Cast welding technology is a composite technology in which molten metal or granular welding material is poured into a lattice formed by pre-welding mild steel to base metal and completely cladded with carbon electrode arc heat.

The forming of a lattice prevents cracks from propagating and exfoliating caused by the effect of layer thickness.

The cladding composite material mainly consists of white pig iron based on high carbon and high chromium, and exhibits extremely superior abrasion(wear) resistance at high temperature.

The dividing of the cladding layer in this process also prevents shrinkage cavities in the final solidification area. FUJICO's cast welding technology is suitable for a layer thickness of minimum 10mm and is capable of coping with any shape and thickness required by the customer.

Products

●Blades for rotary crushers at sintered plants

●Plates at sinter plants

●EST liners

●Liners in continuous-type unloaders

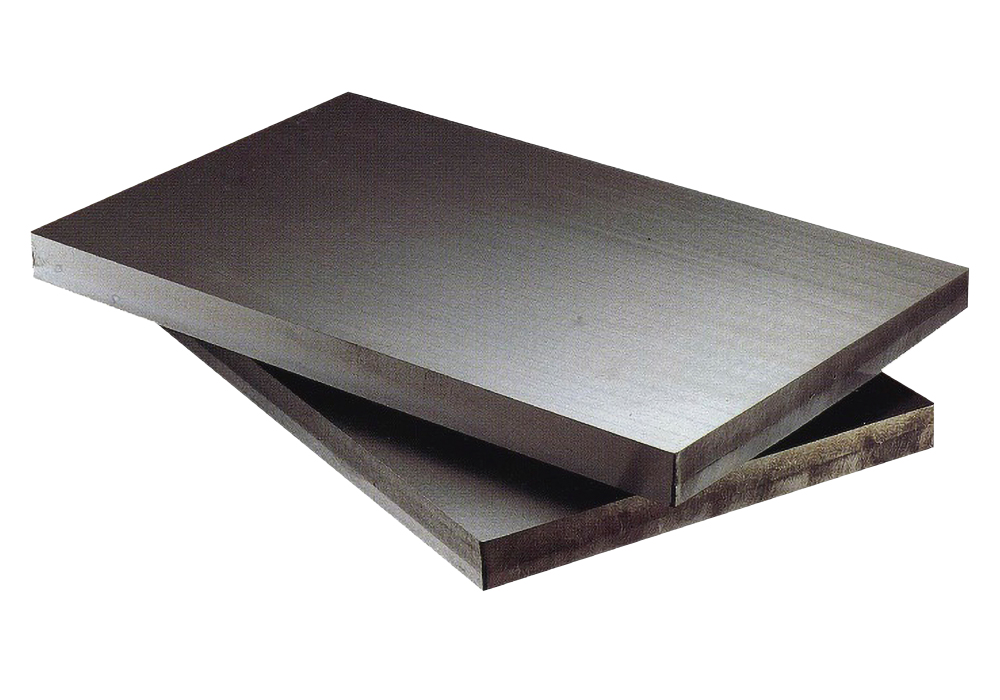

About the Casting Compound Abrasion proof Liner (EST series)

- Structure and shape

-

The composite structure of the EST series liner enables the "coexistence of wear resistance and impact resistance." It consists of an 18mm (or 16mm) cladding layer incorporating a high-chromium cast iron layer with excellent wear resistance and a 12mm (or 9mm) base metal of SS400 with high toughness.